Discover your spiritual companions with a free spirit guide test. Explore the realm of guidance from beyond, uncovering insights into your soul’s journey and divine support. Begin your enlightening adventure today!

What is a Spirit Guide?

A spirit guide is a non-physical being believed to offer guidance, support, and wisdom to individuals on their life journey. These guides can manifest as ancestors, angels, animal spirits, or other entities, each providing unique insights and assistance. Spirit guides are thought to resonate with an individual’s energy, helping them navigate challenges, make decisions, and achieve personal growth. They serve as companions on the spiritual path, offering encouragement and clarity; Understanding your spirit guide can deepen self-awareness and enhance your connection to the spiritual realm, allowing you to align more closely with your life’s purpose and destiny.

Purpose of the Free Spirit Guide Test

The free spirit guide test is designed to help individuals identify and connect with their spiritual companions. By answering a series of thought-provoking questions, users gain insights into their guide’s nature, whether it’s an animal, ancestor, angel, or other entity. This test aims to bridge the gap between the physical and spiritual realms, offering a deeper understanding of one’s spiritual support system. It provides guidance on personal growth, life decisions, and enhancing spiritual awareness. The test is a tool for self-discovery, empowering users to embrace their spiritual journey with clarity and confidence, fostering a stronger connection with their divine guides.

Understanding Spirit Guides

Spirit guides are divine companions offering guidance, support, and wisdom. They connect with individuals to enhance spiritual growth, provide clarity, and align with one’s life purpose and energy.

Types of Spirit Guides

Spirit guides come in various forms, each offering unique support. Common types include animal spirit guides, which embody strength and inspiration, and ancestral guides, who provide wisdom and cultural insight. Angelic guides offer divine protection and love, while nature spirits connect individuals to the earth’s energy. Some individuals are guided by star beings or ascended masters, who share cosmic wisdom and enlightenment. Additionally, deities or higher spiritual beings may serve as guides for those seeking profound spiritual growth. Each type resonates with different personality traits and life journeys, ensuring personalized guidance and support.

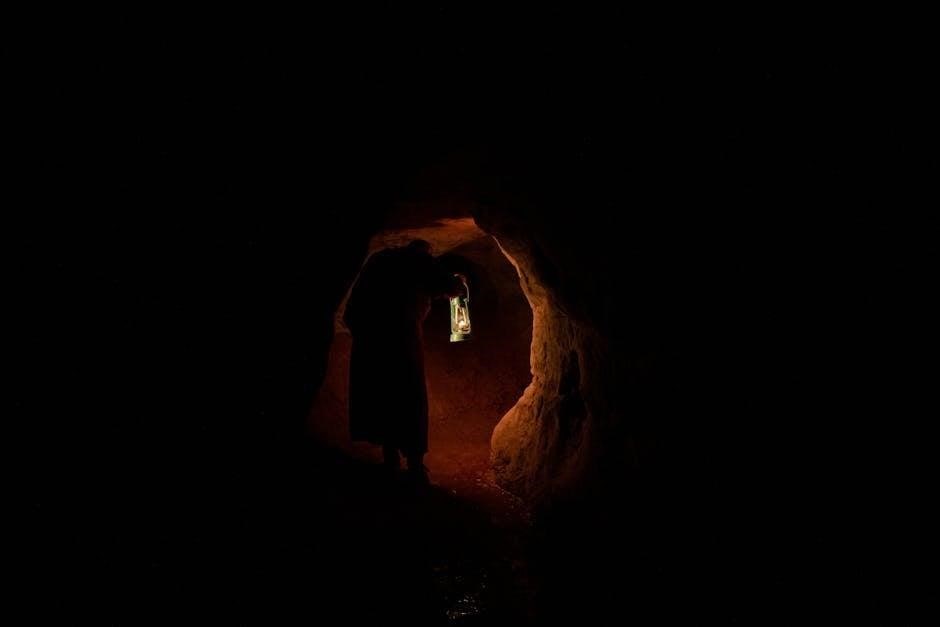

How Spirit Guides Connect with Individuals

Spirit guides connect with individuals through various subtle yet profound methods. They often communicate via intuition, offering gentle nudges or clear insights. Dreams and meditative states serve as common channels for guidance. Some individuals experience recurring encounters with specific animals, symbolizing their spirit guide’s presence. Personality-based tests and quizzes can also reveal alignment with certain guides, such as animal spirits or ancestral beings. These connections are deeply personal, resonating with one’s unique energy and life path. By tuning into these signs and embracing spiritual practices, individuals can strengthen their bond with their guides, fostering a deeper understanding and receiving meaningful support.

How the Free Spirit Guide Test Works

The free spirit guide test uses multiple-choice questions to analyze your personality, preferences, and spiritual inclinations. Responses are evaluated to determine your most aligned guide type, offering insights into their nature and role in your life.

Question Types and Formats

The free spirit guide test features multiple-choice questions designed to assess your personality, preferences, and spiritual inclinations. Queries range from thought-provoking to straightforward, covering topics like life goals, emotional responses, and intuitive feelings. Some tests include image-based questions or scenarios to gauge your innermost connections. The format is user-friendly, with a mix of visual and textual elements to keep the experience engaging. Answers are analyzed to align with specific spirit guide types, ensuring a personalized and meaningful outcome. The variety in question styles ensures a comprehensive understanding of your spiritual profile, making the test both insightful and enjoyable.

Interpreting Test Results

Upon completing the free spirit guide test, you’ll receive a detailed interpretation of your results. The analysis reveals the type of guide most aligned with your energy, such as an animal spirit, ancestor, or angelic being. Your results may include a personalized message from your guide, offering insights into their role and how they can support you. The interpretation also provides guidance on how to connect with your spirit guide, such as through meditation or specific rituals. Some tests offer additional resources, like tips for fostering a stronger spiritual bond. The goal is to empower you with clarity and tools to deepen your spiritual journey, ensuring a meaningful and transformative experience.

Popular Spirit Guide Types

Explore popular spirit guide types, such as animal spirits, ancestors, and angelic guides, each offering unique wisdom and support tailored to your journey.

Animal Spirit Guides

Animal spirit guides are powerful allies that embody the strengths and wisdom of specific animals. They offer guidance, strength, and inspiration, aligning with your personal journey and soul’s purpose. These guides can appear repeatedly in your life, serving as symbols or messengers. For instance, the owl may represent wisdom, while the wolf symbolizes loyalty. Your spirit animal is uniquely attuned to your energy, providing support during challenging times. Discovering your animal spirit guide through tests or personal encounters can deepen your self-awareness and spiritual connection, helping you embrace your true nature and navigate life’s path with clarity and confidence.

Ancestor and Angelic Guides

Ancestor guides are wise beings from your lineage or cultural heritage, offering timeless wisdom and protection. They often appear to provide comfort, share life lessons, or guide you through challenging situations. Angelic guides, on the other hand, are divine messengers of light, offering unconditional love, clarity, and spiritual support. These guides are uniquely attuned to your energy and life path. Through free spirit guide tests, you can identify whether your primary guide is an ancestor, an angel, or another form of spiritual presence. Understanding their role allows you to deepen your connection, fostering personal growth and a stronger sense of purpose. Embrace their guidance for a more fulfilling journey.

The Significance of Knowing Your Spirit Guide

Understanding your spirit guide deepens self-awareness, fostering personal growth and spiritual alignment. It reveals their role in your life, enhancing intuition and guiding decisions for a purposeful journey.

Personal Growth and Self-Awareness

Discovering your spirit guide through a free test fosters profound self-awareness and personal growth. By understanding your guide’s essence, you gain insights into your strengths, challenges, and life purpose. This connection helps you navigate life’s journey with clarity and confidence, aligning your actions with your soul’s intentions. The guidance received enhances your ability to make meaningful decisions, leading to a more fulfilling and purpose-driven life. Embrace this spiritual tool to unlock your potential and embark on a transformative path of self-discovery and growth.

Enhancing Spiritual Connection

A free spirit guide test deepens your spiritual connection by revealing the presence of your guide, fostering a stronger bond with the divine. This test bridges the physical and spiritual realms, allowing you to understand the wisdom and support available to you. By identifying your guide, you gain clarity on their role in your life, enabling you to align your actions with spiritual truths. This connection strengthens your faith and trust in the universe, guiding you toward a more meaningful and purposeful journey. Embrace this opportunity to enhance your spiritual practice and nurture a lifelong relationship with your guide.

Conclude your journey by embracing the free spirit guide test, unlocking insights into your spiritual companions and gaining profound guidance for self-discovery and life’s purpose.

Final Thoughts on Spirit Guide Tests

Spirit guide tests offer a transformative way to connect with your spiritual allies, providing insights into your soul’s journey and life’s purpose. By uncovering your guide’s essence, you gain clarity, empowerment, and a deeper understanding of your path. These tests are not just fun but also serve as powerful tools for self-discovery and growth. Embrace the wisdom they offer, and let your spiritual companions guide you toward fulfillment and harmony. Take the free spirit guide test to embark on this enlightening adventure and uncover the profound connection awaiting you.

Encouragement to Take the Test

Embark on a journey of self-discovery by taking the free spirit guide test. This enlightening experience reveals your spiritual allies, offering guidance and insights into your soul’s path; By participating, you gain clarity on your life’s purpose and unlock the wisdom of your guides. The test is simple, fun, and transformative, making it accessible to everyone. Don’t miss this opportunity to connect with the divine forces that support you. Take the test today and embrace the profound guidance that awaits you, helping you navigate life’s challenges with confidence and harmony.